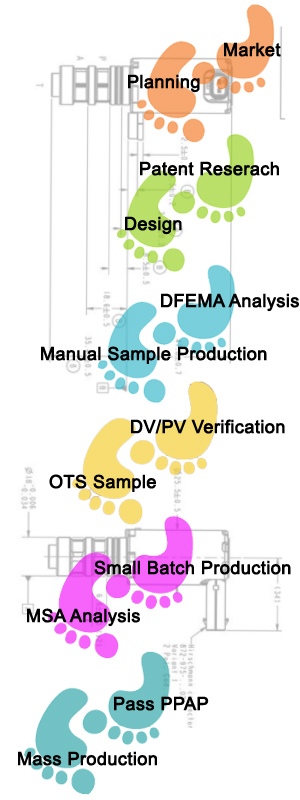

LET'S DISCUSS OUR PROCESS

Our engineering staff proactively communicates their decision making processes to ensure that you have a clear idea of how your program is progressing. These engineering staff will guide you from concept to production, ensuring a transparent working relationship and educating you on the development of your custom solenoid or valve.

One-piece flow, lean manufacturing and rigorous in-house testing ensure that your solution is delivered on time with unmatched consistency and durability. If any questions or concerns arise, engineers and support staff can be easily reached so deadlines and expectations stay on track.

We have carried out every stage of the process control, and the correspondingfeedback matters, assessment and corrective action, in order to better carry out thenext stage of the proces

Product Research

Our engineering team works directly with you to determine the viability of yourprogram and identify the best solution based on your specifications

Design ReviewOur

Our engineering team reviews the design with you and makes any adjustmentsneeded. Prototypes are then bullt according to design specifications for testing purposes.

Test Validation

Prototypes are tested according to your specifications, with all relevant test dataprovided to you for evaluation.

APQP

Our project team will regularly review each process to ensure that each time node of the project is completed successfully

PPAP

Our project team will review the product process, make the product manufacturingprocess plan, and ensure the product error prevention and trace ability.

Continuous improvement

Continue to improve/revise the product to best meet your needs, to improvingetiiciency and lower cosis.